How To Repair Lights On Pre Lit Garland

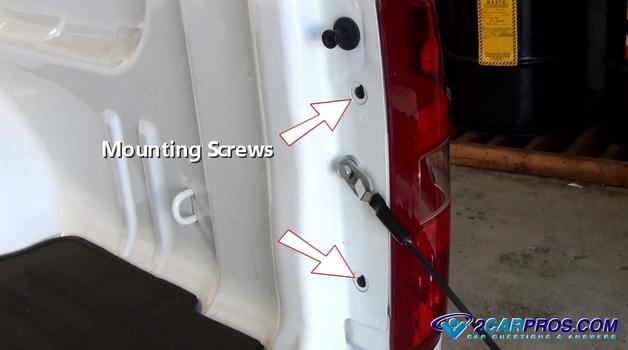

This guide covers a unproblematic bulb replacement and continues onto testing the restriction light electrical system. The restriction low-cal system is a simple on and off exterior lighting organisation which is controlled by a restriction light switch located almost the peak of the brake pedal. A elementary wiring circuit is connected to the automobile's BCM and then onto the rear brake lamps (older cars practice not utilize a BCM - body control module). This system is powered and protected by a fuse located inside the fuse panel nether the dash or the power distribution center located under the hood. When the restriction pedal is depressed by the driver the restriction calorie-free switch completes an electrical circuit. This is achieved by the switch plunger resting against the pedal arm. A stop calorie-free switch is designed in the opposite mode of a normal switch considering when the switch has contact by the pedal it is off, and when pedal is depressed the switch is on. This switch uses a basis trigger for BCM which will turn on the power for the iii brake lights. On older vehicles the switch connects power to the brake lights directly. Some German build cars use a lighting control module in place of a BCM. A brake lamp switch is designed to piece of work with at least two wires and up to six wires in the switch harness. These additional wires are on older cars which send signals to various additional controls in the vehicle such every bit the cruise control, ABS, traction control, shift lock control and BCM inputs. SPONSORED LINKS American made vehicles incorporate the car's blinkers into the brake light circuit. When the turn signal switch or multi function switch is operated the brake lite circuit is substituted for the plow signal circuit for either right or left directionals. European and Japanese cars have a carve up light and circuit for the restriction and turn betoken lights. The most elementary of all brake light problems is the fact that the bulbs simply burn out. This is an quick and piece of cake fix in most cases. Nosotros will evidence you how to supplant these bulbs further on in this guide. As in any electric organisation an open up or short circuit can occur interrupting the operation of one or all of the brake lamps. Lack of power to the brake lights can include: Through fourth dimension and usage the contacts inside the brake light switch can become worn and burn out rendering the switch non operational. A bad ground in the arrangement tin cause the electrical electric current to dorsum feed which makes the bulb dim or dull. A poor connection at the bulb volition make it flicker. If you are having the bulb replaced at a repair shop the cost can exist quite reasonable, between $35.00 and $55.00 (United states). If you are going to supplant the bulb yourself and save the trip to the garage which is what nigh people exercise the seedling volition toll between $5.00 and $viii.00 (US) dollars on Amazon or at the local auto parts store. If the bulbs are okay and y'all have an electrical problem the costs can go upwards considerably which can range from $150.00 to $300.00 (The states) for labor solitary. We volition show yous how to find these kinds of issues further down in this repair guide. Restriction light bulbs should concluding upwards to forty,000 miles or four years depending on driving conditions such as stop and go traffic. When replacing lighting bulbs utilise high quality replacement parts to ensure proper operation and a longer lifespan of the repair. Cheaply made bulbs tend to burn out more rapidly which requires a echo replacement. The electrical portion of the system should exist trouble free for at least 100,000 miles or 8 years. SPONSORED LINKS Potential Tools and Supplies Let'southward start with the well-nigh popular repair which is replacing the brake light seedling so onto troubleshooting connexion and electrical problems. Remove the bulb: At that place are basically 2 styles of bulb replacements which are; The brake lens needs to be removed to access the seedling or the bulb socket can be removed by only twisting it counterclockwise from the backside of the lens either through an access hole which is covered by a small plastic panel or through the trunk, elevator back or hatch. We will show you both types and how to test the organisation in the following guide. Have a helper step on the brake pedal to confirm which restriction bulb is out; correct, left or high center lights. If none of the lights are working then the bulbs are probably not the problem. Although we take seen where all of the bulbs take failed merely considering they had gone bad one at a time in a shut time frame to one other and the automobile owner did non detect or was not informed of the problem by other drivers. When you encounter a person who has a stop light bulb out y'all should exercise the right matter and tell them. SPONSORED LINKS To begin you must determine which style of bulb replacement your vehicle has. This is done by inspecting the lens and looking for mounting screws which hold the lens to the vehicle which can exist on the side of the lens. Yous may need to open up the truck, hatch back, tailgate or lift back. If no mounting bolts are found on the outside of the lens they will exist located in the inside of the rear body panel. Y'all may need to pull back the truck liner or remove a few plastic trim pieces before these nuts or the bulb socket is attainable. If no access pigsty is available y'all must remove the mounting bolts and remove the lens to gain admission to the bulb. In the example below an admission pigsty was provided past the manufacturer which makes the job a footling easier. Sentinel this video of the brake light lens being removed to get an idea of how to do the job. SPONSORED LINKS At present that you have located the light socket and wiring harness the bulb is ready to exist removed for replacement. On virtually American fabricated cars and trucks this bulb has two jobs both for the brake light and the blinker indicator which will accept 3 wires feeding the socket; brake, turn signal, and ground wire. On European and Japanese cars this chore is handled separately which will take but two wires, brake lite power and circuit basis. Grasp the bulb socket and twist firmly counterclockwise. This volition allow the socket to come loose from the lens. Sometimes they can be a little stuck in which instance you can use a pair of pliers to assist break it loose. One time the socket has been removed it volition expose the seedling which may have a burned marker or be light blue in colour which indicates a leak in the drinking glass. In either example the bulb is no good. Grasp the bad bulb and pull information technology from the lite socket. Some bulbs you will need to push button down and twist counterclockwise. SPONSORED LINKS Matching the New Seedling: Once the old bulb has been removed match it to the new unit, they should friction match identically. Pay close attention to the bulb terminals. You do not want to install a two last bulb into the 1 terminal socket and visa versa. This tin can create circuit back feed problems and may maybe accident out the BCM or fuse. Install the New Bulb: Plug the new restriction light bulb into the socket and take a helper push on the brake pedal to see if information technology works. If it does reinstall it back into the lens and reassemble and you are all set. If the light is still not working subsequently replacing the seedling or it is slow or dim then more repairs are needed so continue with the guide. If a restriction light flickers it's considering the ability or footing is being obstructed momentarily. The most common crusade for this is a loose plumbing equipment bulb socket. While a helper holds down on the brake pedal move the bulb around slightly in the socket. If the bulb flickers replace or repair the socket. Also wiggle the wiring to check for opening wiring circuits. This will give you lot an idea of what you're in for before you lot begin. Then follow downward the guide to pick upwardly on additional tips and information. SPONSORED LINKS This is where some testing and ascertainment is needed to repair a bad connection or broken wire. The first half of the guide will troubleshoot ane brake light that is not working while the 2nd half with troubleshoot all or the lower two restriction lights. Test Brake Calorie-free for Power and Ground: Secure the footing clip of a exam light to a known practiced ground source such as a bolt or solid metal slice. It's important to get a good connection free from rust or paint because the test light depends on this conductivity to work correctly which will requite you a skillful test upshot. Wiggle the clip then the teeth of the spring loaded clip dig into the metallic to ensure a practiced connectedness. Have a helper agree down on the brake pedal the remaining working brakes lights should be on. Utilise a test light to probe each of the brake light sockets feed wires; one of them should light upwards. If you cannot discover power and so access the opposite light that is working and probe the wires until power is found to confirm the exam light is working. If power is present at the non working bulbs continue with the guide. If power cannot be establish skip down to: "Testing Brake Low-cal Power" in this guide. If yous have ability at the socket the adjacent pace is to check the system footing. Attach a pointed metal object to the test light prune and probe the restriction lite feed wire and the footing wire of the socket. If the test light lights up the circuit is working and the fault is in the bulb socket connections. If the test light does non low-cal up there is an open up connection in the ground wire. This volition could make the bulb be dim, boring or not work at all. You lot can either make a new ground wire connection by cutting the wire and using a new wire to whatsoever metallic part about the socket or follow the wiring harness and look for obvious damage or cuts in the wiring that will need to be repaired. SPONSORED LINKS Repair Bad Connections: The bulb socket could be subjected to heat and corrosion. Remove the seedling socket and inspect the electrical connector for burned or melted terminals. This is caused by high resistance creating an open connectedness causing the bulb not to work. Manufacturers volition install dielectric grease into the socket to aid protect the connection but with time this clear or brown grease volition melt out and expose the connectors to the temper causing rust or corrosion which causes a bad connection. Use a sharp object such equally an Exacto knife to scrape the connexion clean. If the connections are loose the seedling will flicker and wink. Use a small flat blade (standard) screw driver to enhance the spring load of the terminals. This will aid the bulb connect to the socket making the seedling to piece of work once again. If this socket is badly damaged it should be replaced. With all connections cleaned or socket replaced and the power and basis checked reassemble the socket and seedling onto the wiring harness. Have a helper step on the brake pedal to confirm the bulb functioning. And then reinstall the bulb socket back into the lens and you are all prepare. Many lighting system seedling clusters accept a connector which tin melt due to poor connection which causes high resistance. This resistance tin cause heat which melts the connector plastic creates a bad connection. The connector with pigtail will need to be replaced which y'all can go from Amazon or from the dealer for nearly $35.00 bucks. With the human foot off of the brake pedal cutting the harness and splice in the new connector. If the connector looks okay inspect the wiring harness and look for obvious damage such as a cutting or wear mark indicating the harness has rubbed against a metal frame breaking the wire. If everything looks okay continue with this guide. This portion of the guide is to assistance you test for ability when one, both lower or all three brake lights take no power. Test the Fuses: Use the owners transmission or the lid of the fuse panel to find the brake light fuse. Then use a test calorie-free to check the fuses for the restriction low-cal and BCM fuses and supersede if whatsoever are blown. If the fuse is diddled it could exist acquired by a shorted wire to ground, a melted light socket or a weak fuse. Check to encounter if the fuse is loose in it'southward holder which will crusade a bad connection. Enhance the tension on the holder terminals to correct the problem. If the fuse is okay continue downwards the guide. SPONSORED LINKS Check the Brake Lite Switch: On newer cars using a BCM or lighting module the brake light switch completes a ground circuit which triggers the lighting computer to supply power to the brake lights. Locate the switch virtually the upper part of the pedal which will have wiring connected to information technology. Brainstorm by inspecting the wiring harness and look for obvious harm such as a cut, vesture mark or broken wire indicating the harness has rubbed against a metal frame causing the failure. Wiggle the wiring while pressing down on the the restriction pedal to see if the lights beginning working. This would point an internal broken wire or bad switch. To test the switch use a test light and connect information technology to power and probe each of the two wires. One should be lit all the fourth dimension while the other should light upwardly when pushing the brake pedal downwards. If only one side lights up the switch is bad and needs replacement. On older cars this switch controls brake light power. Perform the same exam using a grounded examination lite. These switches are held in place by a metallic clip and pivot assembly which makes replacement about a 20 minute job in most cases and can be replaced with just a few bones tools. When it comes to electric devices such as restriction light switches, OEM (original equipment manufacturer) the parts work improve and concluding longer. If the switch becomes out of aligning it can go out the brake lights on which can drain the battery down. Since the brake light switch is used many times it volition eventually need to exist replaced. A brake lens and socket tin can melt and distort when the brake lights are kept on for an extended corporeality of time and so try to avoid assuasive the brake lights to stay on overnight. SPONSORED LINKS On vehicles using a lighting or BCM module use a wiring diagram to test the ingoing bespeak from the switch and the outgoing voltage to the lights. If the BCM has a restriction light input signal from the switch and no outgoing signal the brakes lights the module is could exist bad and replacement is required. If none of the lights are working cheque the fuse for the BCM or lighting module. Here is a typical BCM wiring diagram with ability outputs going to the brake lights. They are listed every bit LR Turn Signal (YEL) and RR Plough Indicate (DK GRN) which are the aforementioned as the brake lights on this car. To test the BCM power output connected a basis test light and probe the wires to confirm power or not. (Older American Cars Only) Test the Turn Indicate Switch: On older American vehicles the brake light circuit is routed through the turn bespeak switch which tin become bad non allowing the currant period to go on to the brake lights. Most American cars are designed with the lower restriction light excursion wiring incorporated into the turn signal switch where the restriction light bulb and the turn indicate bulb are one and the aforementioned. The turn bespeak switch interrupts the restriction light circuit and installs the blinker circuit when the switch is activated. Using a wiring diagram test the color wires that are ingoing and outgoing to encounter if the circuit is working. If not supercede the turn signal switch, this is sometimes called a multifunction switch. SPONSORED LINKS Hither is a typical wiring diagram for a organization which powers through a turn signal switch. Once again YEL (E7) and DK GRN (E6) probe these wires while holding down the brake pedal. They should have power and if non the switch is bad and needs replacement. You tin go a wiring diagram for your automobile from an online automobile repair transmission such as Mitchell1 or search Google Images. A dim or dull brake calorie-free is usually acquired past a bad ground or having the incorrect bulb installed or the terminals of the bulb have melted together every bit in the image below. Remove the bulb and make clean the socket terminals or replace the seedling and socket together which will facilitate a lasting repair. If you accept any questions about brake lights delight visit our forum. If you need car repair advice, delight inquire our community of mechanics is happy to aid you and it is always 100% free. Article published 2022-02-08 How Do Brake Lights Work?

What Goes Wrong?

How Much Does It Cost?

How Long Do Restriction Lamps Last?

Getting Started

Checking and Replacing the Bulbs

Pace 1

Step ii

Step 3

Spotter the Video!

Brake Light Not Working After Replacing the Seedling

Step 1

Stride 2

Testing Brake Low-cal Power

Step 1

Stride two

Step iii

Dim Brake Light Repair

Got Any Questions?

Source: https://www.2carpros.com/articles/brake-lights-not-working

Posted by: hernandezbourponshave.blogspot.com

0 Response to "How To Repair Lights On Pre Lit Garland"

Post a Comment